Our Security Initiatives

We are leaders in maritime cargo security, working to ensure safe and efficient movement of cargo through our network and beyond.

Security

Certified ISPS Code Compliant

Adopted by the International Maritime Organisation (IMO), ISPS Code is an international framework through which ships and port facilities must operate to detect and deter international terrorism, for which we have gained certification and compliance with since June 2004. To ensure effective security measures are maintained and improved, we conduct quarterly security drills and annual exercises in a simulated large-scale incident jointly with the port authority, the marine department, the local police, and emergency services.

Truck Driver Identification

As a gateway port with a large volume of containers and trucks moving in and out of the port area, we must identify truck drivers quickly to ensure a secure and seamless process for the receipt and delivery of containers at terminal check in-gates. Hutchison Ports Thailand has integrated citizen identity card readers to our terminal operating system as one of the controlling access measures so that we can identify truck drivers quickly and efficiently in our system. This takes only 3 seconds per transaction which causes no delay to our gate operations.

Safety First

We operate a stringent “Safety First” policy, striving to mitigate the risk of injury to our employees and port users. This commitment applies not only to our own employees and partners, but encompasses all visitors to our facilities. We have invested into improving safety in areas where employees work closely with machinery and to provide better separation for the different types of traffic in a terminal. These include measures like clear signage, increased use of high- visibility clothing and barriers, and better communication of traffic and safety rules on the terminal.

Safety Drills

We also hold regular safety drills to ensure all staff are up-to-date with the latest safety procedures. The drills we run not only help staff to respond rapidly and effectively in real emergency situations, but also mentally prepares them to make quick decisions under pressure. Developing team work and confidence in our staff is of the utmost importance in assuring that safety is always at the forefront of everyone’s mind at our terminals.

Verified Gross Mass (VGM)

On 1 July 2016, to improve the overall safety of the supply chain at sea an initiative was launched requiring every packed export container to have its weight verified before being loaded onto a vessel. All shippers must comply with this mandatory container weight verification by providing this information to both the carrier and container terminal operator prior to the cargo being loaded onto a vessel.

Environmental Policy (ISO 14001:2015)

The Company commits to conduct the activities in environmentally friendly way throughout the life cycle by managing the use of resources in an efficient manner, prevent and reduce environmental impacts from operating activities in all process as well as to focus on the development of business and investments that do not sustainably cause problems to the environment by following the actions below.

- Strictly comply with law, requirements, and other regulations related to the environment.

- The modern technology is used for the operations by focusing on the most efficiently use of resources and energy saving including the encourage of using alternative energy.

- Build consciousness to all employees by providing knowledge, understanding, and raise awareness about the impacts on using natural resources to the environment.

- Encourage and support employees, contractors, customers, and service users of the Company to cooperate in energy and environmental conservation, maintain the cleanliness and hygiene as well as to circular economy activities.

-

- Create an environment of the company to be clean, beautiful, shady and lively and conducive to the efficient and safe operations.

- Effectively prevent and control pollution by managing the quality of air, dust, solid waste, wastewater and chemicals as well as minimize the occurrence of waste from all activities process.

- Prevent the occurrence of incidents and accidents that may occur during the operations which will affect the environment both internal and external the organization as well as the preparation to resolve any situation that may occur.

- Reduce, where feasible, the production of green houses gases, ozone depleting emission and other air pollutants within HPT’s operation.

- Emphasize the cooperation of all departments in the organization in performing the duties along with environmental protection with the unity of all employees by cooperating and participating in environmental projects or activities. If there is any problem or any unusual event found, report the commander for further corrective actions.

- The company’s commitment is to provide support for carrying out various activities to sustainably meet and achieve the mentioned policy frameworks.

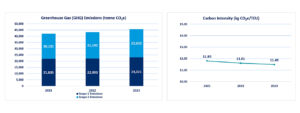

Environmental Performance

Remarks:

- Scope 1 Emissions (tonne CO2e) is the GHG emissions from sources that are owned or controlled by the port.

- Scope 2 Emissions (tonne CO2e) is the GHG emissions from the generation of purchased electricity, steam,heat and cooling.

- Carbon Intensity (kg CO2e/TEU), is the total of Scope 1 and Scope 2 GHG Emissions divided by the port’sannual throughput.

- The emission factors applied for the calculation of Scope 1 are adopted from the U.S. Environmental Protection Agency and Department for Environment, Food, and Rural Affairs (UK).

- The emission factors applied for the calculation of Scope 2 GHG Emissions are adopted from the International Energy Agency.

Hotline

Call us if you would like to report an incident:

+66 38 408 700 Ext. 4191

For further information regarding access to port facilities contact the relevant port facility security officer in Contacts.